About Shufflebottom

Established in 1977, Shufflebottom is recognised as one of the UK’s leading manufacturers of award-winning steel-framed buildings for the agricultural & equestrian and industrial & commercial sectors. We also produce high quality structural steelwork for construction projects across the UK and beyond.

Buildings can be ordered as kits for customers to erect, or with our erection service.

Shufflebottom is an award-winning, family-run business with a purpose-built seven-acre site strategically positioned just off the M4 at Cross Hands, south Wales. Since 1977 we have taken pride in the detailing, design, manufacture and supply of steel-framed, industrial & commercial and agricultural buildings for a diverse range of clients and projects.

Today, we are proud to be one of the UK’s leading manufacturers of steel-framed buildings for industrial & commercial, agricultural and community use.

We’re a growing and continually developing company with family-values still at our heart, a turnover of £25 million+, 85 staff, multiple sub-contractors, additional sales offices in the east of England and Scotland, and a growing portfolio of projects for main contractors and major construction projects across the UK.

We are committed to growth and working hard and smart on behalf of our customers. We know the cost and value of quality and excellence and so we invest heavily in our design and production staff, apprenticeships and in our processes.

To ensure we maintain competitive edge, we make ongoing investment in our production capability, including top-of-the-range Peddinghaus integrated system machinery enables us to combine high-performance, versatility and increased productivity, with a capacity of 1,000 tonne structural steelwork production per month, to serve all our customers’ needs as we approach a new era in our business.

Projects include:

Arenas & Grandstands

Barns

Equestrian buildings

Factories

Grain stores

Offices

Pig Units

Showrooms

Sport Centres

Superstores

Retail Units

Warehouses

Shufflebottom sector brochures

You can download a PDF of our sector brochures by clicking on the images.

Structural Steelwork brochure

Industrial & Commercial brochure

Agricultural & Equestrian brochure

“We have been working with Shufflebottom for over 30 years now and their buildings have always been professionally built, delivered and to specifications as required. Shufflebottom are a thoroughly professional organisation with approachable and competent staff who over the years have supported us through our various farm building projects. I have no hesitation in recommending Shufflebottom”

– Martin, J & M Bodman Ltd

Our manufacturing process

Shufflebottom is committed to delivering projects that are that extra bit special. This commitment is why today we’re one of the UK’s major independent players in the structural steel sector and why our company has won numerous awards for the buildings we’ve delivered.

Every building is detailed by our engineering team and manufactured by our highly-skilled fabricators at our on-site factory at Cross Hands. We also have in-house design capacity if required. In this integrated way we can respond to a client’s individual needs efficiently and effectively, paying attention to detail, offering design advice and proposing the right materials, finishes and features for a specific project.

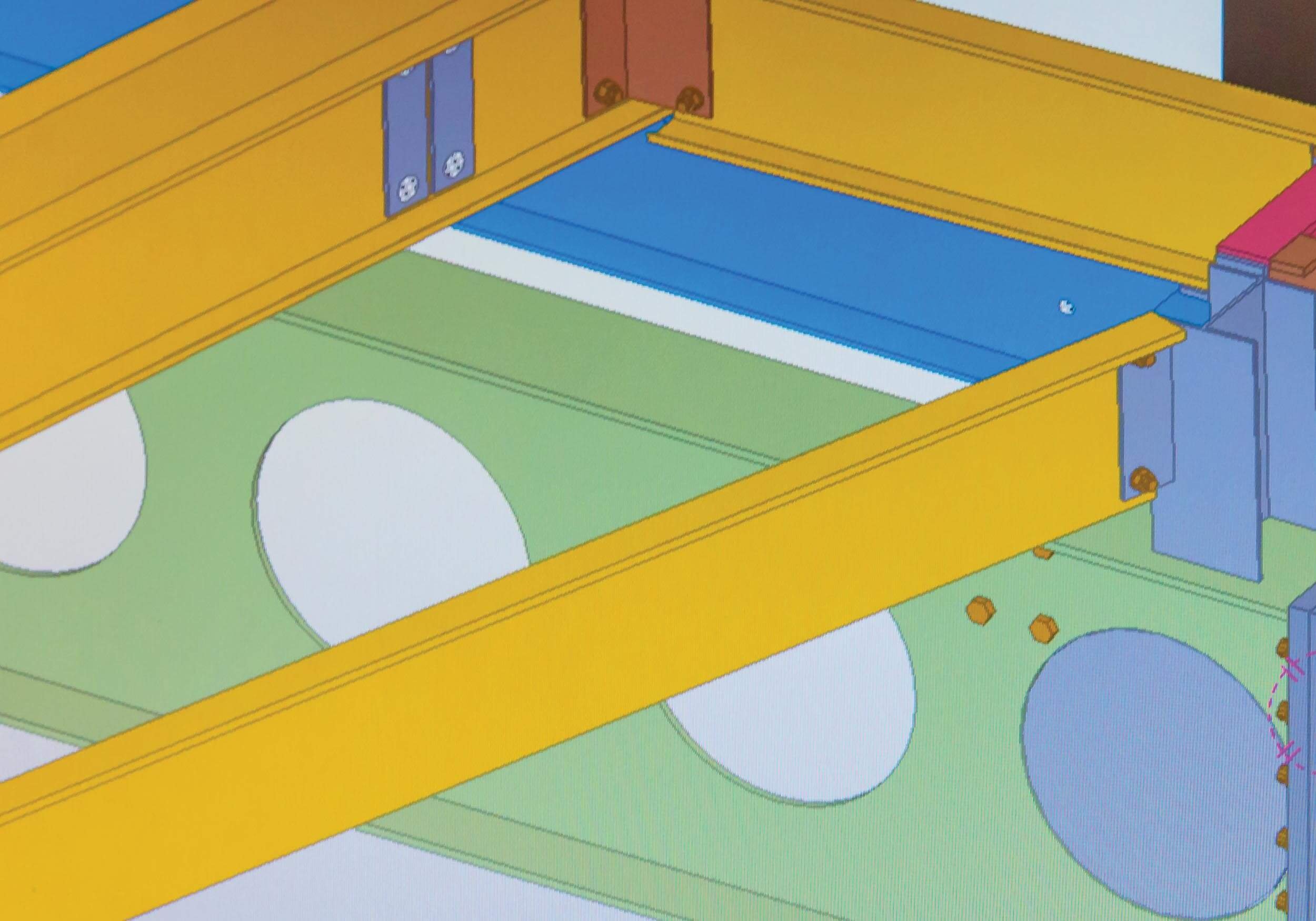

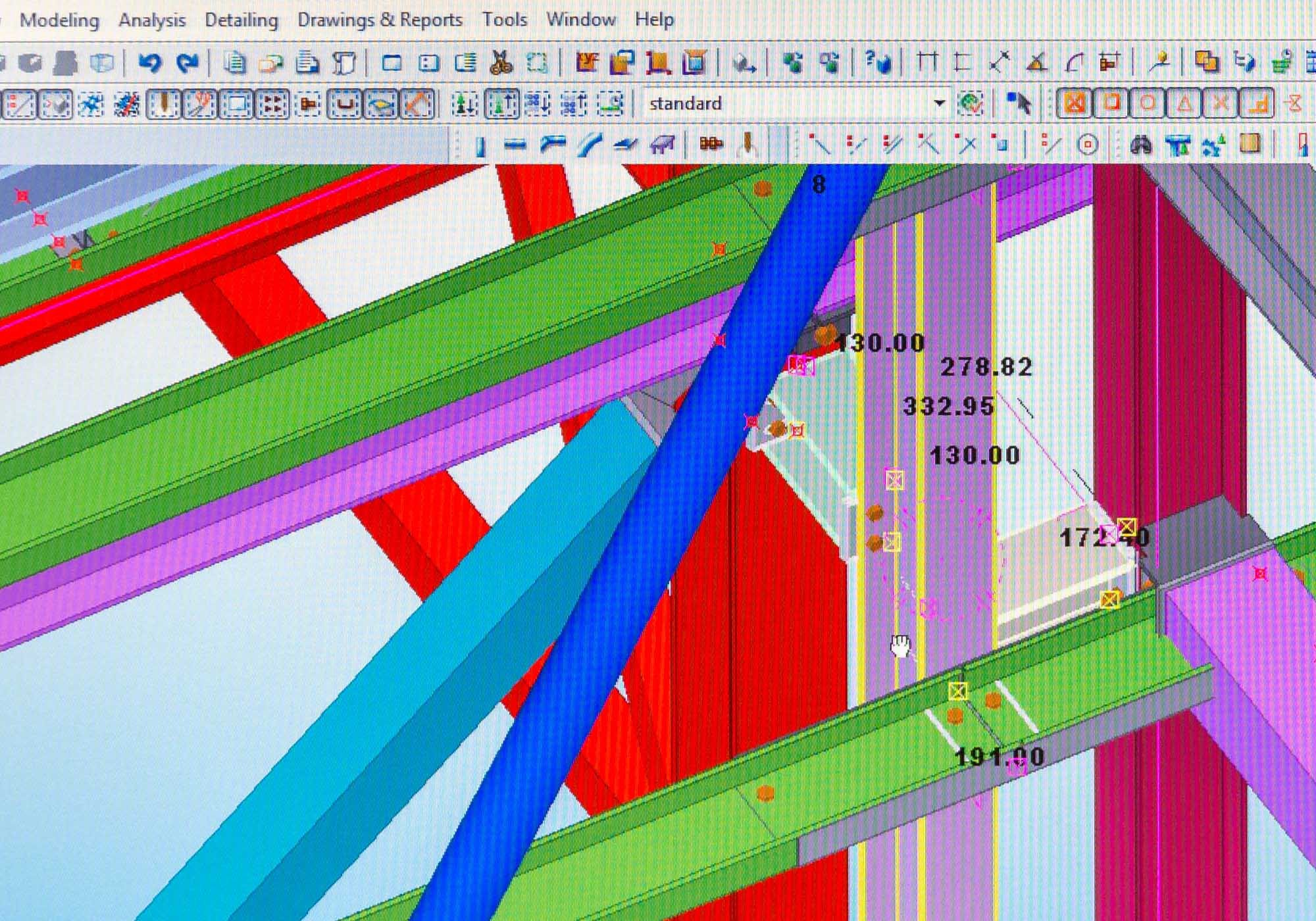

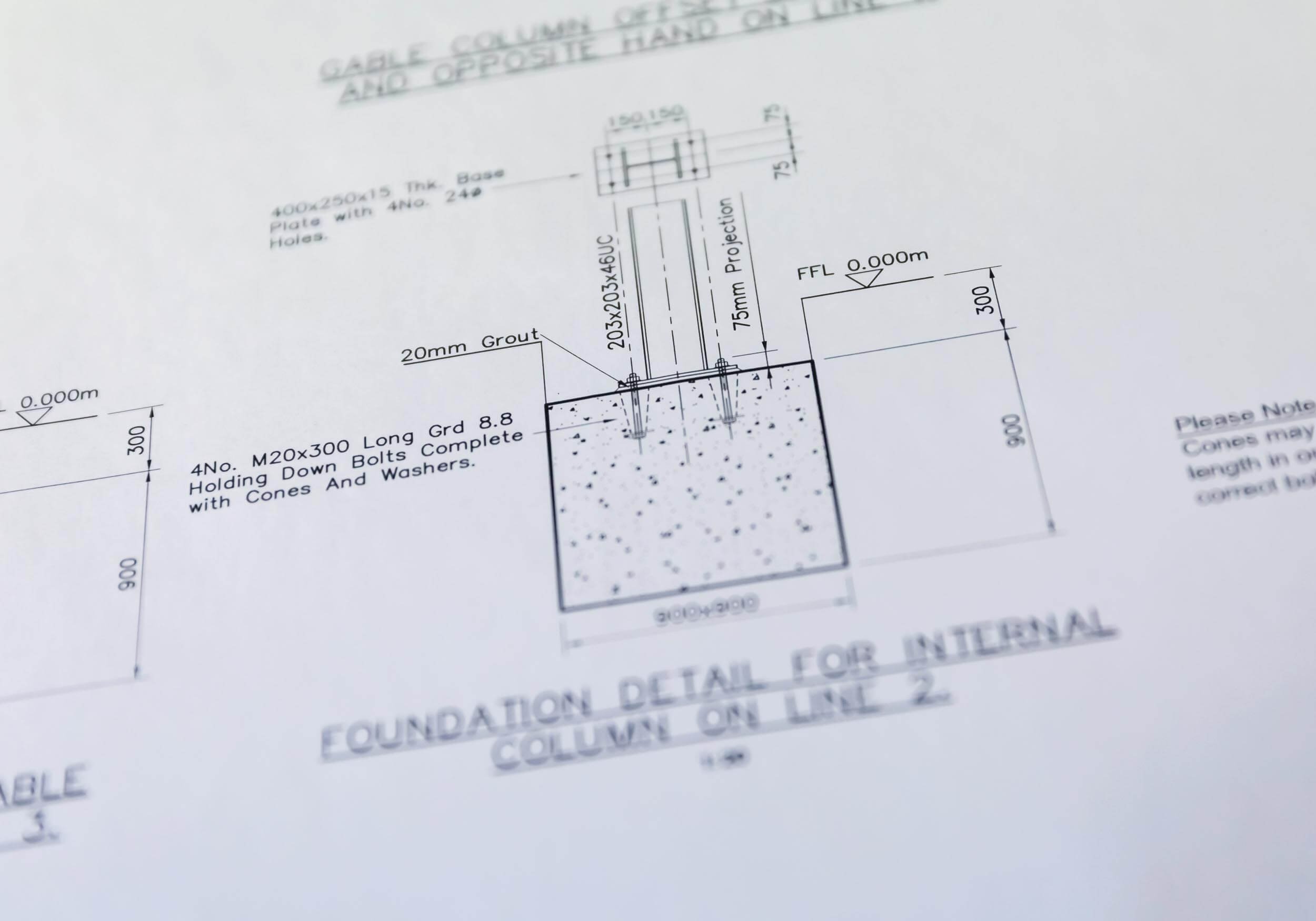

At Shufflebottom, our draughts people utilise the latest in 3D modelling software as an integral element of the detailing and planning stage ahead of the steel fabrication process. The software gives valuable insights and tools enabling the team to formulate accurate, detailed plans and drawings that can be communicated to the steel fabrication team, to turn a vision into reality and create buildings that are fit for purpose.

Shufflebottom makes use of Building Information Modelling (BIM), an intelligent modelling software system created for the planning, design, construction and management of a building. This ensures digital representations of the physical and functional characteristics of a building and provides a central accurate and reliable store of information about that building at all points in its life cycle.

In this way we can deliver a seamless service for our clients, from drawing board to finished product, and at every stage along the way.

We aim for the Shufflebottom brand to be synonymous with quality in all aspects of its operations. That’s why we continue to invest in efficient systems, cutting-edge technology and innovative equipment to enhance our business, maintain competitive edge, ensure maximum return on investment and position ourselves for further growth.

Importantly, our focus on machine productivity, efficiency and innovation enables us to work smarter and faster on behalf of all our customers.

Stock yard

Storage space for 800+ tonne of hot rolled steel means that economies of scale apply so we can buy in bulk at best possible prices, efficiently and quickly, on behalf of our customers.

Cutting

We have two beam processing lines including blasters, a Voortman cut and drill line and our Peddinghaus DG-1250 mitre Band Saw has the capability of cutting a wide range of mitre-cuts, from straight cut through to 60 degrees, and responds to programme command or manual input. Cutting edge technology gives us high performance, versatility and increased productivity.

Drilling

As well as our Voortman cut and drill line, our Peddinghaus CD-1100/3C-Advantage-2 high-speed carbide Drill-Line has the capability to process all structural shapes – beams, channels, angles and tubes, making for super efficiency as part of a modular, integrated Peddinghaus cut, drill and blast system.

Plasma

Our new Esprit Lightning plasma machine combines the latest laser cutting principles with the latest plasma cutting technology which enables us to produce clean, square, dross free cuts for our profiles and more.

Fabrication

Quality control is paramount in our Shufflebottom processes. After tack-welding and inspection, our qualified welders complete the welding requirements to our engineers’ details.

Roll-forming and sheet-metal machines

In addition to the design and manufacture of structural steelwork we also have our own in-house roll-forming sheet-metal machines for the manufacture of single-skin cladding profiles and flashings and trims.

Paint facility

We have an in-house paint facility where a post-fabrication primer is applied to the steel – typically, a high-build zinc phosphate primer though other coatings can be applied too. As well as paint, there is the option for steelwork to be galvanised instead.

Cladding

Shufflebottom offers a range of cladding options for our buildings including composite panels, fibre cement and box profile cladding.

Composite panels

Insulated cladding panels, commonly referred to as composite panels, are made up of an insulated core that is bonded between an exterior and interior metal skin. The composite panels we supply are available in a range of colours, core thicknesses as well as profiles.Fibre cement

Shufflebottom uses Profile 6 fibre cement cladding, which has polypropylene reinforcement strips to maximise impact strength, and is used for roofs with pitch of 5 degrees and over. Fibre cement has definite environmental advantages – it is fully recyclable, and is manufactured using the low-energy Hatschek process, which combines cement, wood cellulose, synthetic fibres, relevant additives, water and air to form this durable construction material. Other advantages of fibre cement are its malleability and high strength in relation to thickness.Single skin box profiled cladding

When it comes to roofing and wall cladding, single skin can be manufactured in-house with Shufflebottom’s own roll-forming machines, in a wide variety of colours. Shufflebottom started producing its own profiled cladding some 30 years ago to ensure we could control quality, demand, and customer lead times. Box profile 1000/33 is available in plastic-coated finish in a choice of colours in 0.5mm and 0.7mm gauges, with cover width of 1 metre. Single skin box profile is also available in Vent Air & Fleeced backed cladding from outside suppliers.

Samples of all cladding are available on request.

Plastic colours

Polyester colours

Steelwork – Painted or Galvanised

Shufflebottom can provide a painted finish or a galvanised finish to the steelwork for a building.

Painted Steelwork

Shufflebottom shotblasts steelwork for a building to B.S. SA 2.5 and then paints with 75 microns Zinc Phosphate High Build Primer, generally in Hollybush Green. However, we offer many more colour options.

Galvanized Steelwork

Steel is galvanized by placing it in a bath of molten zinc at 450degC. The iron in the steel reacts with the zinc to form zinc/iron alloy layers. When the steel is slowly withdrawn from the galvanising bath, unalloyed ‘free’ zinc is also drawn out and solidifies over the alloy layers, forming the smooth, bright finish that is characteristic of hot-dip galvanising.

Concrete panels

Pre-stressed concrete panels on Shufflebottom buildings are available in a range of thicknesses, including 95mm, 145mm, 180mm, 200mm and 280mm. They are also available in a range of heights. Pre-stressed concrete panels, which can offer increased security, can be used in a range of applications including stock panels, grain walling and general walling.

Doors

Shufflebottom understands that a new building may require doors to suit a particular farm site. We can manufacture or supply many different types of doors including gates, sliding doors, roller doors, and high-security personnel doors. Doors can be colour-coded to match a specific building, and constructed to suit standard or non-standard openings. With over 30 years’ experience of manufacturing farm buildings, Shufflebottom can also advise on door fittings and other features.

Kit or Erect buildings

Shufflebottom buildings are available as supply-only in kit form as well as erected by us.

Kit buildings

Shufflebottom buildings can be supplied in kit form for a customer to erect themselves. This has many advantages including kit buildings generally having a shorter lead time than erected buildings as a customer does not need to wait for one of Shufflebottom’s erection teams to become available. By choosing to erect their own building, a customer can put the building up in their own time, and bring in other trades at a time that suits them. For example, a customer might choose to put the steel up and then build walls, or finish a floor before the cladding. An additional benefit is that a customer’s own plant, machinery and labour for the erection of the kit building can be utilised. If a customer chooses a kit building option, Shufflebottom is still happy to provide technical in-house back-up during the build and answer any questions.

Erect buildings

Shufflebottom buildings can also be supplied with our erection service, meaning that we can will erect and clad a building on a customer’s behalf. As part of this service, we can provide all the plant and labour needed to erect the building.

Business opportunities

Shufflebottom is proud to have many customers who regularly source kit buildings from us and sell them to their customers as part of a full package.

Safety, Health, Environment & Quality

At Shufflebottom SHEQ is one of our core values throughout our operations without compromise; including manufacturing and installation..

All welding operatives are trained and coded to the latest British Standard BS EN ISO 9606-1 with welding procedures BS EN 15614-1

Welding Quality Management System certificated to BS EN 3834-2:2021 accreditation body SCCS (Steel Construction Certification Scheme)

Our competent teams of erectors are highly qualified in nationally recognised standards such as the Construction Plant Competence Scheme (CPCS), National Plant Operators Registration Scheme (NPORS), International Access Powered Federation (IPAF) and Fall Arrest Safety Equipment Training (FASET)

Our manufacturing supervisors and foremen are trained in the supervision of managing health and safety, and hold such qualifications as Institute of Occupational Safety & Health (IOSH)

We are members of the Royal Society for the Prevention of Accidents (ROSPA) and proud winners of Gold and Silver Awards. We are multi Gold Award Winners of the annual RIDBA Training Awards. Other accreditations include Construction Line, CHAS, Builders Profile, British Safety Council Members, BSG and Sustainability School.

Shufflebottom integrated management system including Safety, Health, Environmental and Quality is accredited under the International Organisation for Standardisation (ISO), ISO 9001, ISO 14001 and 45001

CDM Regulations

Construction Design & Management Regulations (CDM), identifies a number of key elements to securing construction health and safety. These include: managing the risks to health and safety by applying the general principles of prevention, which set out the principles duty holders should use to direct their approach to identifying the measures necessary to control the risks to health and safety in a particular project.

We aim to reduce the provision of generic information, and to only provide specific information that should help with the communication, co-ordination and risk management of projects. We actively monitor our health and safety performance to ensure we operating safer and healthier.

UKCA

Our steelwork falls under the UK Conformity Assessed Manufacturing standard, demonstrating compliance with the manufacturing standard required.

CE Marking

CE marking is a declaration that a product reaches the relevant EU Legislation, which in the case of Structural Steelwork is BS EN 1090. Shufflebottom were one of the first companies to gain the CE Mark in the UK when it became mandatory legislation in July 2014. We are certified to EXC3.

Policies and legal obligations

Please click on the links below to view / download our various policies and legal obligations.

Company Policies/Certificates

Website

Job vacancies

Shufflebottom is a large, continually developing company with family-values still at our heart, a turnover of £25 million+, 85 staff, multiple sub-contractors and additional sales offices in the east of England and Scotland.

We are an Equal Opportunities Employer and winner of the 2019 RIDBA Training Award. Therefore, we are always looking for skilled, hard working and dedicated people to join us across a wide skills’ range. Please see our latest vacancies if you are interested in working with us.